Ne, Chemical symbol of Neon, a colourless gas, an unassuming element happens to play a critical role in making the tech we use every day. For years, this Ni has also mostly come from Ukraine, where just 2 companies purify enough to produce devices for much of the world, usually with little issue. At least, they did until Russia Ukraine crises.

However, Ukraine’s Neon industry halted production is not the potential impact on tech manufacturers.

There will be ripple effects, though. Semiconductor manufacturers rely on Neon to control the specialized lasers they use to make computer chips. It is not clear whether they have enough time to find and develop new source of this gas before their backup supplies run out. Chip companies and industry analysts say there’s anywhere between Ne in reserve. If that runs out, these companies won’t be able to make semiconductors. This means that the worldwide chip shortage. Which was expected to end sometime in the next year or so, leading to higher prices, delivery delays, and shortages of critical technology.

This shortage is a grave reminder that technology manufacturing is spread throughout the world and across different companies, some of which are clustered in a single country. Hardware companies like Apple, Samsung, and Intel tend to like this approach because they buy components from specialized third-party manufacturers, which allows them to cut down on labor costs and assemble devices. What the ongoing conflict in Ukraine makes clear, however, is that this system is also precarious, and that a snag in the production of even the most basic component or ingredient can jeopardize the world’s access to all sorts of tech.

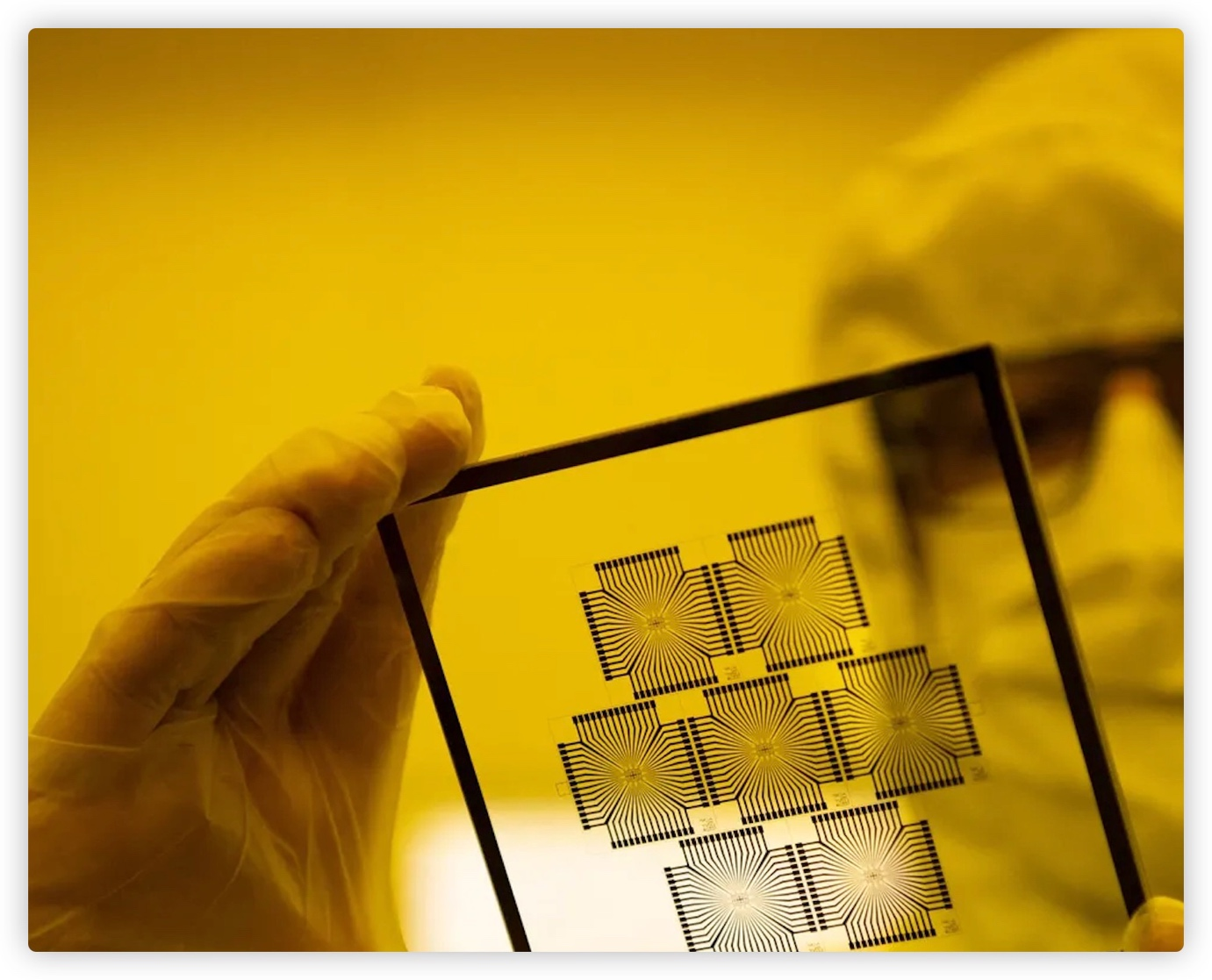

Chip manufacturers generally don’t produce their own neon. Still, they need the gas to operate the highly precise laser they use to turn silicon, into the tiny circuits that make computers work. These lasers play a primary role in a step called lithography, which comes after long silicon cylinders, sometimes called ingots, have been sliced into thin sheets of silicon, which, wafers and often resemble CD-ROMs. Manufacturers use these lasers to etch tiny, delicate patterns onto the glass, which starts the process of transforming a sheet of silicon into a sheet of chips. Because these chips are so small and intricate, though, manufacturers need to control wave length of light that emitted by their lasers.

Over the past 2 years, the worldwide semiconductor shortage has made this clear again and again. Covid-19 outbreaks at chip manufacturing plants continue to slow down device production. Now, automakers are selling cars without parts, and alarm companies are struggling to replace obsolete home health devices and security systems — all because there still aren’t enough chips. In this sense, the conflict in Ukraine is just another issue of how the shortage of an often unnoticed component or ingredient has the capacity to cascade and throw the entire technology industry off course.

Countries are racing to backtrack from this approach to making semiconductors. Japan, China, South Korea, and the European Union have all started or plan to invest billions of dollars to develop their own chipmaking capabilities. What the neon shortage has also highlighted, however, is that the chip industry is highly dependent on a wide range of components. If shortages of these components can prolong the chip supply crunch, they will certainly hold back the coming chip renaissance.

This may also cause the reshuffle of the supply chains and logistic hubs for Chip industries. Nexteck Singapore Pte Ltd, key customers have recently discussed on expending our weight% of local (production lines) supply of chip packaging materials, like WLSCP carrier tapes, cover tapes and dicing tape.

Big players in Chip industry, like some of our clients want to be less surprised, which is why they’re throwing a lot of money at developing a more self-sufficient (surely, more costly). But now, the global tech supply chain remains a house of cards, which still depends on the world generally being in a good place, one where there aren’t wars or pandemics. Unfortunately, this is not the world we live in.

But anyway, and no matters what, Nexteck Group will stand side by side with our customers if, in needed.