In Semiconductor and Packing Materials industries, like WLCSP class precision carrier tape and cover tape manufacturer, Nexteck Singapore Pte Ltd. We deeply understand that contamination is a huge source of production issues and product failure in semiconductors and microelectronics, making cleanrooms critical for the manufacture and packaging of semiconductors is the main concern of www.nexteck.com.sg.

In the production plants of Nexteck Group all cleanroom environments must be engineered to control static, particulate matter, out-gassing, and other sources of contamination and compromising conditions. Our cleanrooms offering balance environmental control with flexibility, ranging from the extremely high level of control over static, humidity, contamination, and pressure offered by our Class 100 HardWall cleanrooms to Class 100,000 capable SoftWall cleanrooms which strike a balance between our production lines for Nexteck Singapore Pte Ltd., packing materials class of carrier tapes and cover tapes for normal LED grade to our Precision class WLCSP carrier and cover tape for wafer and chips grade for semiconductor industries customers.

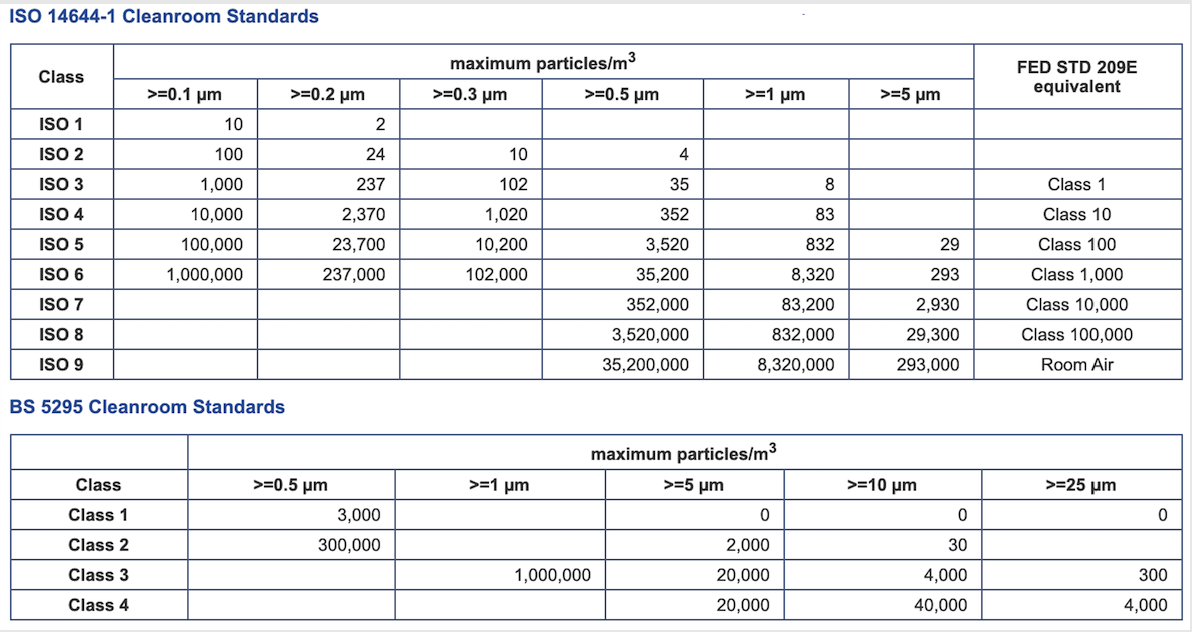

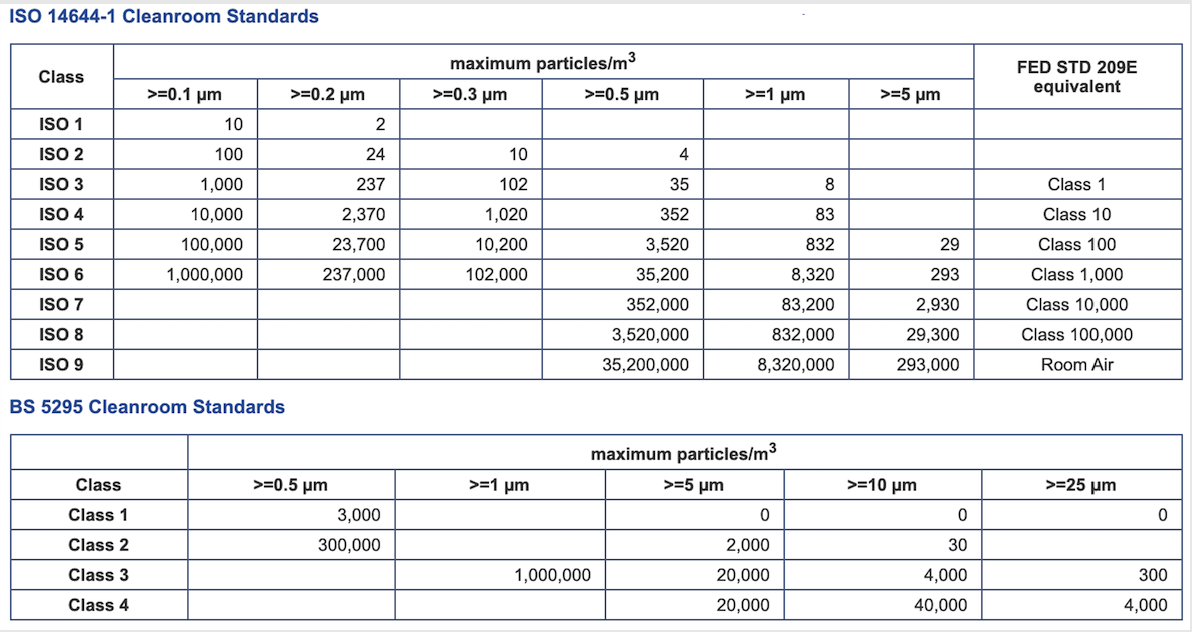

Cleanrooms are classified by how clean the air is. In Federal Standard 209 (A to D) of the USA, the number of particles equal to and greater than 0.5µm is measured in one cubic foot of air, and this count is used to classify the cleanroom. This metric nomenclature is also accepted in the most recent 209E version of the Standard. Federal Standard 209E is used domestically. The newer standard is TC 209 from the International Standards Organization. Both standards classify a cleanroom by the number of particles found in the laboratory's air. The cleanroom classification standards FS 209E and ISO 14644-1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area. In the UK, British Standard 5295 is used to classify cleanrooms. This standard is about to be superseded by BS EN ISO 14644-1.

Cleanrooms are classified according to the number and size of particles permitted per volume of air. Large numbers like "class 100" or "class 1000" refer to FED_STD-209E, and denote the number of particles of size 0.5 µm or larger permitted per cubic foot of air. The standard also allows interpolation, so it is possible to describe e.g. "class 2000."

Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 µm or larger permitted per cubic metre of air. So, for example, an ISO class 5 cleanroom has at most 105 = 100,000 particles per m³.

Both FS 209E and ISO 14644-1 assume log-log relationships between particle size and particle concentration. For that reason, there is no such thing as zero particle concentration. Ordinary room air is approximately class 1,000,000 or ISO 9.

Below is the standard of which Nexteck Singapore Pte Ltd is maintained in the production for our Packing materials products of cover tape and carrier tapes for semiconductors class customers.

For inquiry of Semiconductor grade WLCSP Carrier tape and reels and WLCSP Cover tape and reels, Nexteck Group Specialist are more than welcome to support you on info@nexteck.com.sg.