Technical Note of WLCSP Carrier, Cover Tape Packing Spec.

The WLCSP family has been designed to ful-fill the same quality levels and same reliability performance as standard semiconductor plastic packages. As a consequence these new WLCSP can be considered as new surface mount devices which are assembled on a printed circuit board (PCB) without any special or additional process steps. In particular these packages do not require any extra underfill to increase reliability performance or to protect the device. These packages are compatible with existing pick-and-place equipment for board mounting. Only Lead-free RoHS compliant WLCSP are available in mass production.

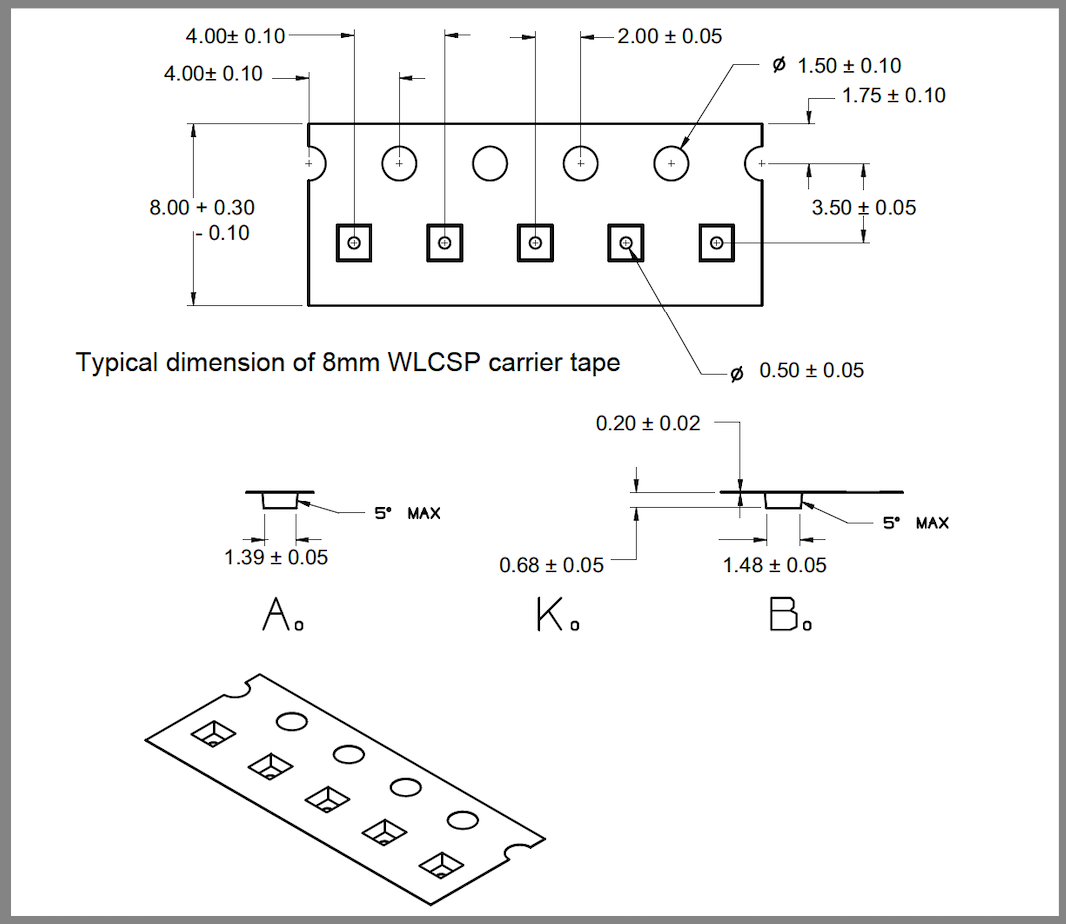

WLCSP Carrier tape

The WLCSP are placed in carrier tapes with their ball side facing the bottom of the cavity so that the devices can be picked up by their flat side. No flipping of the package is required for mounting on the PCB. The devices are positioned in the carrier tape with pin A1 on the sprocket hole side.

The cavities in the carrier tape have been designed to avoid damaging the components. No hole is present in the cavity to avoid any impact or any external contamination of the solder bumps.

The embossed carrier tape is in a black conductive material (surface resistivity within 104 and 108 Ω/sq). Using this material prevents the component from being damaged by electrostatic discharge and ensures the total discharge of the component prior to the placement on the PCB.

Conductivity is guaranteed to be constant and is not affected by shelf life or humidity. The material does not break when bent and does not have any powder or flake residue that rubs off.

Precision Cover tape (for WLCSP)

The carrier tape is sealed with a transparent antistatic (surface resistivity ranging from 105 Ω/sq to 1012 Ω/sq) polyester film cover tape using a heat activated adhesive. The cover tape tensile strength is higher than 10 N.

The peeling force of the cover tape ranging from 0.1 N to 0.7 N in accordance with the testing method EIA-481-C and IEC 60286-3.

Cover tape is peeled back in the direction opposite to the carrier tape travel. The angle between the cover tape and the carrier tape is between 165 and 180 ° and the test is performed at a speed of 120 ± 10 % mm/min.

Nexteck Singapore Pte Ltd is a leading supplier for Reel and Tape and Semiconductors packing materials like WLCSP cover and carrier tape in Singapore, Malaysia, Thailand and the Philippines.